The SMC Flex Controller is a versatile industrial control solution designed for motor management and automation. It offers advanced features, compatibility, and user-friendly operation;

1.1 Overview of the SMC Flex User Manual

The SMC Flex User Manual is a comprehensive guide designed to assist users in understanding and operating the controller effectively. It covers installation, configuration, and troubleshooting, ensuring smooth integration into industrial systems. The manual includes detailed wiring diagrams, parameter settings, and diagnostic techniques to address common issues. Key features like voltage unbalance detection and motor operation halt are explained to ensure safe and efficient performance. The document also provides instructions for downloading parameter values using DriveTools software and communication modules. Available in PDF format, the manual serves as an essential resource for programmers and operators, offering step-by-step guidance for optimal controller functionality in various industrial environments.

1.2 Key Features and Functionalities of the SMC Flex Controller

The SMC Flex Controller is a high-performance industrial control solution offering advanced motor management capabilities. It features voltage unbalance detection, halting motor operation if deviations exceed set thresholds. The controller supports parameter customization, enabling tailored configurations for specific applications. With compatibility across various industrial systems, it integrates seamlessly into existing infrastructure. Additionally, it offers IoT connectivity, supporting communication protocols for enhanced monitoring and control. The controller’s modular design allows for flexible scalability, adapting to diverse operational demands. Its user-friendly interface simplifies programming and operation, while built-in diagnostic tools facilitate troubleshooting. These features make the SMC Flex Controller a robust and versatile option for industrial automation and motor control systems.

Installation and Setup

The SMC Flex Controller installation involves hardware setup with wiring diagrams and software configuration; Refer to the quick start guide for step-by-step instructions and parameter settings.

2.1 Hardware Installation and Wiring Diagrams

The hardware installation of the SMC Flex Controller involves mounting the device and connecting it to the motor and power supply. Ensure all wiring matches the provided diagrams in the user manual. Proper grounding is essential for safe operation. Connect the motor terminals to the controller’s output, and verify the power supply connections. Use the wiring diagrams to ensure correct terminal assignments. Follow safety standards to avoid electrical hazards. Refer to the manual for specific instructions tailored to your system configuration. Additional resources, such as the quick start guide, offer step-by-step instructions for a seamless setup process. Always double-check connections before powering up the system.

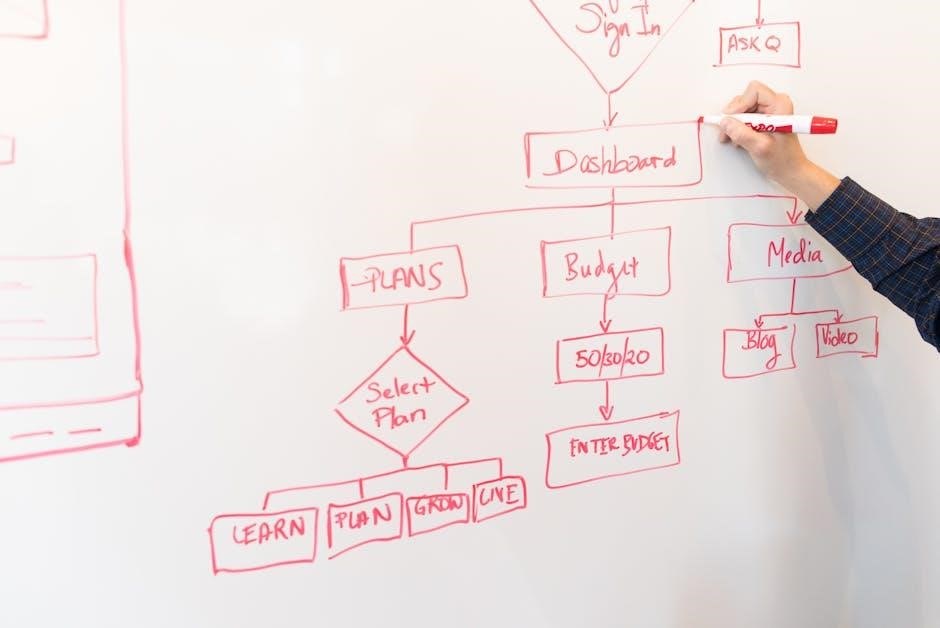

2.2 Software Installation and Parameter Configuration

The software installation for the SMC Flex Controller requires downloading and installing the DriveTools programming software. Connect the controller to your PC using the Cat. No. 20-COMM DPI communication module. Launch the software and select the appropriate controller model. Parameter configuration involves setting values such as motor ratings, starting modes, and protection levels. Use the provided spreadsheet or manual to input the correct settings. Ensure all parameters align with your application requirements. After configuration, download the parameters to the controller. The software also allows real-time monitoring and adjustments. Refer to the user manual for detailed instructions and troubleshooting tips. Proper configuration ensures optimal performance and safety of the motor and connected systems.

Operation and Control

The SMC Flex Controller provides intuitive operation and control, enabling users to monitor and adjust motor operations in real-time. Its user-friendly interface ensures efficient management of industrial processes.

3.1 Basic Operating Modes and Parameter Settings

The SMC Flex Controller offers multiple operating modes, including Current Limit, Fixed Speed, and Variable Speed, to suit various industrial applications. Users can easily configure parameters such as acceleration and deceleration times, voltage, and frequency to optimize motor performance. The controller also features a user-friendly interface for setting thresholds and enabling advanced functionalities. Parameter settings can be adjusted via the control panel or through the provided software tools, ensuring flexibility and precision. These configurations allow for tailored control of motor operations, enhancing efficiency and reliability in industrial environments. Refer to the user manual for detailed instructions on setting up and managing these modes effectively.

3.2 Advanced Control Features and Customization

The SMC Flex Controller offers advanced control features, enabling precise customization to meet specific industrial needs. Users can program custom parameters, such as voltage ramp rates and current limits, to optimize motor performance. The controller supports IoT integration, allowing real-time monitoring and remote adjustments through compatible communication protocols. Additionally, the system provides diagnostic tools for proactive maintenance and fault detection. Customizable alarm settings and event logging enhance operational oversight. These features, combined with user-friendly software tools, enable tailored control solutions for complex industrial applications; The SMC Flex Controller’s adaptability ensures it can be configured to suit a wide range of automation requirements, making it a robust choice for modern manufacturing environments.

Troubleshooting and Maintenance

The SMC Flex Controller includes diagnostic tools for voltage imbalance detection and parameter adjustments. Regular maintenance ensures optimal performance and longevity, supported by DriveTools software for parameter downloads and customization.

4.1 Common Issues and Diagnostic Techniques

Common issues with the SMC Flex Controller include voltage imbalances, communication errors, and incorrect parameter settings. Diagnostic techniques involve checking wiring diagrams, monitoring operational parameters, and using DriveTools software for real-time data analysis. The controller’s built-in tools detect voltage unbalance and halt operations if thresholds are exceeded. Users can troubleshoot by reviewing error codes, verifying parameter configurations, and ensuring proper software updates. Regular maintenance, such as updating firmware and cleaning connections, prevents malfunctions. Refer to the user manual for detailed diagnostic procedures and repair guidelines to ensure optimal performance and extend the controller’s lifespan.

4.2 Maintenance and Repair Guidelines

Regular maintenance of the SMC Flex Controller ensures optimal performance and longevity. Inspect connections and clean terminals to prevent malfunctions. Replace worn or damaged components using genuine repair parts listed in the manual. Firmware updates are essential for resolving bugs and enhancing functionality. For repairs, refer to the user manual or Rockwell Automation’s Product Compatibility and Download Center (PCDC) for guidance. Use DriveTools software to verify parameter settings and diagnose issues. Always follow proper safety protocols when servicing the controller, such as disconnecting power before performing repairs. Scheduled maintenance and timely repairs prevent unexpected downtime and ensure reliable operation in industrial environments.

Compatibility and Integration

The SMC Flex Controller seamlessly integrates with industrial systems, IoT solutions, and communication protocols, ensuring compatibility and efficient operation across diverse applications and environments.

5.1 Compatibility with Industrial Systems and Devices

The SMC Flex Controller is designed to seamlessly integrate with a wide range of industrial systems and devices, ensuring compatibility and efficient operation. It supports various motor control applications, including pumps, fans, and compressors, making it a versatile solution for industrial automation. The controller is part of the PowerFlex series, which is known for its adaptability to different industrial environments. It supports multiple communication protocols such as EtherNet/IP and Modbus, enabling easy integration with existing industrial networks. Additionally, the SMC Flex Controller is compatible with Rockwell Automation systems, ensuring smooth operation within established industrial ecosystems. Its modular design allows for customization to meet specific application requirements, making it a reliable choice for diverse industrial needs.

5.2 Integration with IoT Solutions and Communication Protocols

The SMC Flex Controller supports advanced integration with IoT solutions and various communication protocols, enhancing industrial automation capabilities. It is compatible with Rockwell Automation’s PowerFlex series, enabling seamless connectivity to industrial IoT platforms. The controller supports protocols like EtherNet/IP, Modbus, and DeviceNet, facilitating real-time data exchange and remote monitoring. This allows for efficient system optimization and predictive maintenance. Additionally, the SMC Flex Controller can be programmed using DriveTools software, ensuring customized control and monitoring. Its compatibility with IoT communication standards makes it suitable for modern smart factory environments, enabling enhanced performance and scalability in industrial applications. This integration capability ensures the SMC Flex Controller remains a cutting-edge solution in industrial automation.